Description

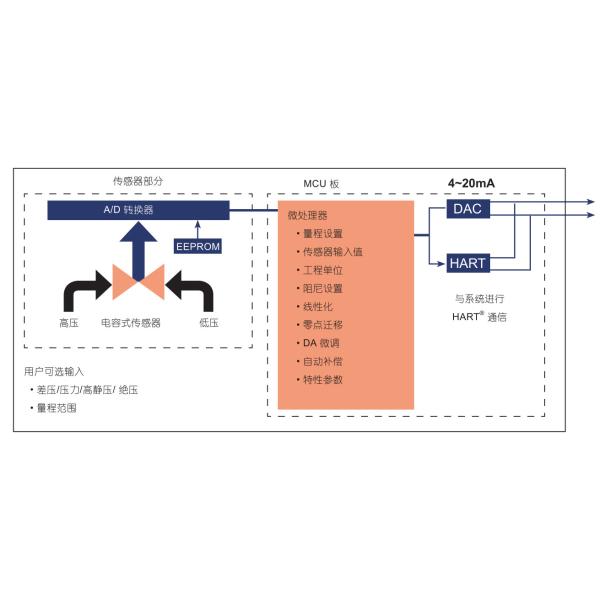

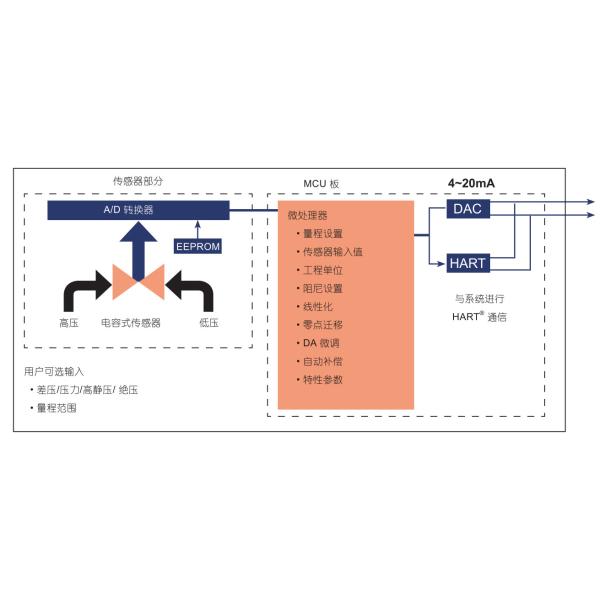

RP62 is equipped with a microprocessor that can measure a variety

of pressures, supports multiple outputs and multiple parameter

settings, and can implement HART ® communication functions and

other operations. According to the usage method, pressure

measurement, flow measurement and liquid level measurement can be

performed.

Specification

| Process interface materials | Process Isolation Diaphragm: 316L SS, Hastelloy C-276, Monel,

Tantalum |

| Process interface: 316SS, carbon steel (galvanized), Hastelloy,

Monel |

| O-ring gasket: Teflon, fluorinated rubber |

| Exhaust/drain valve: 316L SS, Hastelloy C-276 |

| Bolt: Carbon Steel, A286 SS (NACE) |

| Note: There are other special anti-corrosion materials available

for the wetted parts, which can be used under various working

conditions. Please contact VIRVO ® Company |

| Mounting brackets | Carbon steel (galvanized) or stainless steel angle brackets, carbon

steel flat brackets |

| filling fluid | Silicone oil DC200 or CTFE (fluorine oil) |

| watch case | Epoxy polyester paint, low copper aluminum alloy. Meets NEMA 4X

(waterproof) and NEMA 7 (explosion-proof) requirements, available

in stainless steel |

| process connection | 1/4NPT, 1/2NPT conversion joint (optional) |

| Wiring | 16AWG (1.5mm diameter) |

| net weight | 4.2kg, about 5kg including accessories |

| Package Size | 234X185X155mm |

| Nameplate | 304 stainless steel |

| Hazardous area certification | With explosion-proof and intrinsically safe certification, it can

be used in Class I, Devision 1, Group A, B, C, D situations, and

non-flammable Class I. |

| Devision 2, GroupA, B, C, D occasions. ATEX standard EEx ia ⅡCT4,

T5, T6 and EExd ⅡCT5, T6 certification |

Electrical indicators

| voltage | 11.9~45 VDC | output signal | 4~20mA DC/HART |

| HART load resistor | 250~1500Ω | Insulation voltage | 500 Vrms (707VDC) |

| Damping time | 0.25S | Start Time | 5S |

Performance

| Accuracy | ±0.075% of span |

| (0.2URL≤Span≤URL) |

| ±[0.05+0.005x(URL/Span)]% |

| of Span(0.05URL≤Span<0.2URL) |

| Stability | ±0.01% full scale/year |

| Temperature effect | ±[0.025%URL+0.125% Span]/28 |

| Vibration effect | The frequency on any axis is 200Hz, and the error caused is

±0.05%/g of the measuring range. |

| Power supply voltage effect | 0.005% full scale/volt |

| CE certification | 89/336/EEC, electromagnetic compatibility (EMC) standard |

Operating environment

| parameter | Rated environment | operating limits | transportation and storage |

| Ambient temperature (℃) | -40~85 | -40~91 | -55~125 |

| Surface temperature (℃) | -40~110 | -40~125 | -55~125 |

| Humidity (%RH) | 10~85 | 0~100 | 0~100 |

| Overvoltage capability | 14MPa, special up to 21MPa |

| Vacuum degree (KPa) | 0 | 3.5 | -- |

product structure

Precautions

The use of a transmitter side exhaust / drain valve, taps should be

installed to the side

flow pipeline. Working medium for the level, exhaust gas / liquid

discharging valve arranged

on the flange of the upper to exhaust gas; working medium for the

gas, vent / drain valve

installed in the lower flange to discharge liquid; flange rotation

of 180 DEG, side exhaust /

drain valve from the upper to the lower.

Note: The measurement of steam or other high temperature media,

medium

temperature can not contact with the transmitter over its use for

temperature limit.

When measuring steam, the pressure inside the tube must be filled

with water, to

prevent direct contact with steam and transmitter. Because the

volume change quantity

transmitter is very small, so it does not require the condenser.

Pipeline pressure port connecting the transmitter and the measured

media is a

transmission channel pressure, the pressure transfer process,

factors may introduce error

include

1) Loss of pressure

2) The friction loss of pressure pipe

3) The accumulated gas of pipeline in the liquid medium

4) The accumulated liquid of pipeline in the gas medium

Installation with mounting bracket

2 inch pipe vertical bracket

Features

/MULTIPLE INPUTS

Differential pressure type (DP), gauge pressure type (GP), absolute

pressure (AP)

/MULTIPLE OUTPUTS

4 ~20mA (analog), digital signal output

Ambient temperature automatic compensation function

/AUTOMATIC COMPENSATION

/PARAMETER SETTINGS

Zero/quantity conversion, fault alarm, unit conversion, fine

adjustment, etc.

/DIGITAL COMMUNICATION

HART communication various commands 5

/APPEARANCE

CSA,FM,ATEX,GOST6

/FEATURE

High accuracy: ±0.075% of span(±0.04% of span)

Stability: ±0.01%/year

High turndown ratio: 100:1

/FLEXIBILITY

Parameter setting via HART ® protocol commands

Zero point adjustment (Zero point adjustment) 8

/RELIABILITY

Mean time between failures of 20 years; continuous self-detection

function (sensor, memory, communication); automatic compensation

function (ambient temperature compensation, sensor input

linearization); software and hardware fault alarm function;

configuration protection: EEPROM write protection function; CE EMC

standards (EN50081-2, EN50082-2)

Packing & Delivery

FAQ

1. Q: What information need to be provided to choose the suitable

model?

A: Application field, Nominal pressure ,Medium & medium temperture

, Power supply , Output,

Flow range, Accuracy, Connection and other parameters.

2. Q: Are you a trade company or a manufacturer?

A: We are an ISO approved manufacturer specialized in level and

flow measuring instruments.

OEM & ODM service are available. Welcome to visit us in China.

3. Q: What is your MOQ?

A: To start our cooperation, sample order is acceptable.

4. Q: What is your delivery date for the Intelligent Mini Micro

Turbine Fuel Oil Diesel Flow Meter?

A: The delivery date is about 3-15 working days after receipt of

payment.

5. Q: What is your payment terms?

A: We support T/T, PayPal ,Western Union.

For mass production order, it is 30% deposit in advance and 70%

balance before shipment.

6. Q: Do you have a warranty for the Flow Meter?

A: Yes, we have the warranty of 12 months.